Innovative Solutions

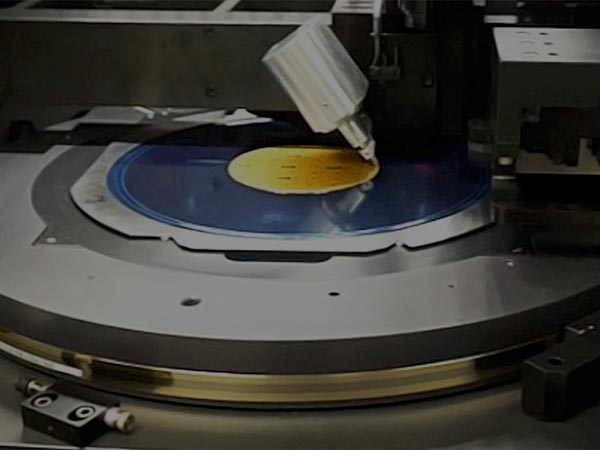

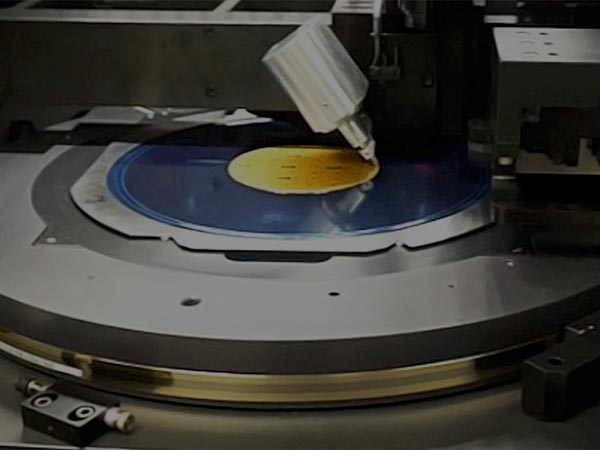

We promote customer success in a wide range of wafer dicing applications through a commitment to quality and superior service.

We promote customer success in a wide range of wafer dicing applications through a commitment to quality and superior service.